lol wait til you decide to go SR6 with twist and a t-valve.

I am honestly impressed what your servos are able to do with just USB Power.

15 each sadly isn’t much for servos. I also ordered those servos, after i accidentaly fried my old servos of my SR6.

You can also have a look in here for more Servo tests/information.

There are also other threads for that topic.

lol, I was gonna go for an SR6, but thinking of how often i use multi axis with current osr2+ kind hold back the thought

Thx

never mesured the current, but it works so why bother lol

Hey there. Sorry I was busy the last few days and couldn’t have a good look.

I want to preface this with that I tend to over-engineer such things so be warned ![]()

That lag is indeed weird. To make it worse, it is the same lag in seconds (or video frames in this case) for both 100 and 200 BPM. Which would mean it scales with speed when looking at the phase lag, while the amplitude decreases. But before jumping to conclusions, there might just be a communications delay. Do you also see this lag with MFP? And can you achieve no lag on ayvaStrokerLite, when slowing down with the same configuration?

P.S. You not noticing any difference with 15A vs. probably 500-900mA seems absolutely crazy to me. Those must be some magic servos or USB ports ![]()

I’ll test it later

At lower BPM yes, at least not to my eyes can notice

I’ll try to measure the current later then

That won’t be necessary. I was just astonished. As long as we know, the servos have enough power now and that the wiring is good (power bus highly recommended), that’s ok.

The thing that’s leading me to eliminate the torque as the limiting factor, is that it is the same lag for both the top and lower points. I would assume, if the torque was limiting, then the lag at the bottom point would be shorter than the top one (gravity).

So that leaves the speed limitation and/or a communications delay (Browser-UART-USB-ESP32-ServoElectronics-Servo). Now if indeed the lag does not appear at slow BPM’s, then it is most probably the speed limitation.

For reference, for my OSR2+Twist (which is out of commission at the moment because of a mechanical failure of the main walls ![]() - so I can’t test it to compare right now) I use brushless BLS6028 which deliver 22.5 kg*cm and 0.15 s/60° at 4.8V. Scripts with 600 units/s (basically 200 BPM at 100% range) can just about run fine using a Fleshlight but take that with a grain of salt, because I haven’t tried that out much, since that’s just way too excessive for my taste. It also depends on other factors like how much pitch and roll angle there is and how much friction there is.

- so I can’t test it to compare right now) I use brushless BLS6028 which deliver 22.5 kg*cm and 0.15 s/60° at 4.8V. Scripts with 600 units/s (basically 200 BPM at 100% range) can just about run fine using a Fleshlight but take that with a grain of salt, because I haven’t tried that out much, since that’s just way too excessive for my taste. It also depends on other factors like how much pitch and roll angle there is and how much friction there is.

So if your goal is to run those speeds around 600 units/s (200 BPM at 100% range) consistently and with alot of angles and friction, you’ll most likely need better speed AND a bit more torque. But generally speed is the limiting factor in your case:

0.22s/60° → 450 units/s → 136.6 BPM @ 100%

200 BPM @ 100% → 600 units/s → 0.15s/60°

So from your initial two candidates (if you haven’t found any other good candidates with all the helpful links in this thread), I don’t think any of those are going to be satisfying. If I had to I’d go for the G25. BUT: they will deliver less than 22kg*cm at 5V (if they can run at 5V).

P.S. I just realized that I could have arrived at the same conclusion of speed limit by doing these calculations first instead of the phase-analysis of your video ![]()

Thanks for all the math and physics. ![]()

now that I think of it, 0.22s/60deg for simplicity let’s assume full length uses 60deg which means a full stroke(up+down) will take 0.44s at least, this is a lil bit faster than 2 stroke per sec(400units/s), if consider the acceration and speed lost due to load, it is very possible less than 2 stoke per sec. Which is close to your calculation

I found another one has the same speed as G25 with 35Kg.cm torque but simular price as X20 (lil cheaper than X20)

Don’t wory I will buy a proper power supply if i’m gonna change into a servo works in different voltage range

just measured the current, and I think I know why I didn’t notice any difference between usb and pc power module. It is bc the whole thing somehow only uses just a lil above 800mA with 200BPM, around 700mA with 100BPM, 800mA with 130BPM think it max at here just as you calculated.

surely theres something wrong with these servos or theres something wrong with the power module if they are meant to drain more current

That ain’t very much. Theoretically, if the servos are running in their speed limit all the time, the speed controller or the motor’s field weakening could be reducing the torque. You would only see those spikes and flattening in the power consumption if you used an oscilloscope (which I assume you don’t just have lying around) and if there isnt’t a large enough capacitance at the servo’s DC-Bus to filter that out (very unlikely). But let’s not delve too deep into that.

Much more likely, there might be a problem with your power wiring or - as you’ve stated - the servos themselves. Are you feeding power through the ESP32 or are you using a power bus? And secondly, the resistance of your connections (or servos) might be too high therefore limiting current and therefore power, heating up wires instead of generating movement.

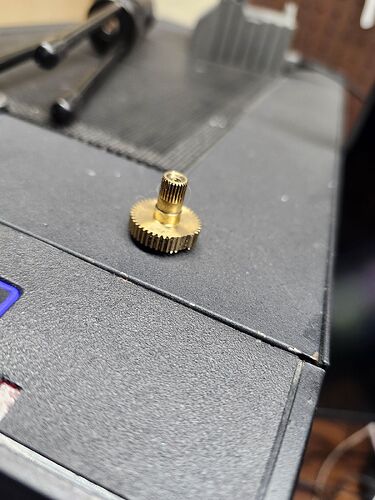

Is it normal for the servo gears to completely tear away after the first time. I def dont think these stock ones are strong enough to do the job

I was also getting weird movement and skips so after a quick teardown i noticed that gear in the servo box was thrashed

Don’t know how a servo will fail, but surely not just in a single use

O7

Don’t know what a power bus is but I’m using the pc power module when doing the tests (which should have more than enough power).

This is the roughly circuit I use

btw, I’m using Arduino nano instead of ESP32

It seems like there is builtin capasitor or inductor inside the servos, bc I can’t get a persist resistance reading from the GND and PWR pins on the servo, It keeps raising the reading

I have only seen servo gears shear off like that unless something forced it way beyond it’s limit, such as an RC heli crashing. Any chance you accidentally dropped it or nudged it hard while it was powered on? Could also be just very cheap servos.

any new updates @kamakamaChan ?

I did not drop anything but I did probably use it too much during an edging sesh and those cheap servers just gave way. No issues with the SSR1

Brass is just a step above plastic for servo gears. You should go with a servo that has steel gears. Even those, mind you, can get broken with heavy use.

I bought 2 of this baby

it has more torque and faster.

I’m feeding it w/ 7.4V4A switching power supply so it has 80ms/60deg w/ 31kgcm torque acrodin to the casing

here’s tests without load runing 200bpm on Ayva. the lag is bearly noticeable even under 1/8 speed

And as for real use I don’t feel any previous problems. Only problem is this thing is too strong that it snaped a 14cm arm that is for roll and stroke, and bended the 14cm arm that is for pitch. probably bc of my onahole is kind heavy so the arm couldn’t move it fast enough so it snaped to the side

yea, those arms are way too thin. My arms are printed from PLA at 15% infill and 7mm thickness.

Also…that tin metal looks…sharp. I know you’re trying to make a budget build, but to add perspective; imagine yourself in a session with a fast bouncing script and those arms get bent. This means the onahole would not be properly aligned and your dick will slip out while the OSR is still slamming at full speed. You’ll mince your dick up.

My pp did slip out a few times before but nothing bad happened, pp just slip into the gap between onahole and the holder.

So it’s not that scarry ig